The Basics of Chip on Board (COB) LEDs

by Rich Miron

Media Reports

What are COB LEDs?

Relatively new to the LED market, chip on board (COB) LEDs offer many advantages over the standard options. COB LEDs are basically multiple LED chips (typically nine or more) bonded directly to a substrate by the manufacturer to form a single module. Since the individual LEDs used in a COB are chips and not traditionally packaged, the chips can be mounted such that they take up less space and the highest potential of the LED chips can be obtained. When the COB LED package is energized, it appears more like a lighting panel than multiple individual lights as would be the case when using several SMD LEDs mounted closely together.

Figure 1: A COB LED example - the Bridgelux Vero™ Array Series.

Advantages of COB LEDs

Being multi-chip packaged, the light-emitting area of a COB LED can contain many times more light sources in the same area that standard LEDs could occupy resulting in a greatly increased lumen output per square inch.

COB LEDs use a single circuit with just two contacts to energize the multiple diode chips it houses. This results in fewer components required per LED chip for proper operation. Furthermore, the reduced components, along with the elimination of the traditional LED chip structure packaging, can reduce the heat generated from each LED chip. The ceramic/aluminum substrate of COB LEDs also acts as a higher efficiency heat transfer medium when coupled to an external heatsink, further lowering the overall operating temperature of the assembly. When mounting a COB to a heatsink, care must be taken to choose a heatsink capable of dissipating the heat generated to enable a COB to be used to its full potential. In the long run, the proper heat dissipation increases efficiency and lowers failure rates.

Another aspect of COB LEDs that reduces failure rates is the fact that spot soldering of the individual LED chips is not necessary as each chip is directly mounted onto the substrate. The smaller amount of welding points results in lowering the rate of failure.

Light loss is decreased significantly and viewing angle is increased both due to the fact that lenses and other traditional LED packaging parts are no longer in place when using COB LEDs.

The disadvantage of COB LEDs

COB LEDs do have one disadvantage in that they currently are available in a limited variety of colors (blue, green, pink, red, cool white, neutral white, and warm white).

Applications for COB LED lighting

The application possibilities for COB LEDs encompass a wide range. While these devices could be used for higher output general lighting, the primary use for COB LEDs would be as solid-state lighting (SSL) replacements for metal-halide lamps in applications such as high-bay lighting, street lights, and high-output track lights and downlights.

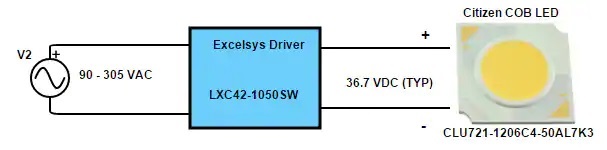

Figure 2 shows the basics required to get a COB LED powered up. This illustration uses an Excelsys Technologies LXC42-1050SW driver to provide a constant 1.05 A to a Citizen CLU721 Series COB LED.

Figure 2: Basic COB LED circuit block diagram (Diagram drawn using Digi-Key Scheme-it)

With an input voltage range of 90 to 305 VAC, the driver is capable of supplying up to 1.05 A to the COB LED (which, in this case, has a test current of 1.05 A and a maximum rating of 1.38 A) and will not be damaged by over-driving it. Additionally, when drivers are run closer to their maximum capacity (in this example 39.48 W out of a 42 W maximum), they operate with higher efficiency, contributing towards fewer losses in the overall system.

Conclusion

The use of COB LEDs in lighting applications is increasing as designers realize the benefits of using them over the traditional standard LED options. With their ability to pack more LED sources into a smaller space for increased lumen output, their ability to transfer heat more effectively to a heatsink, the lower failure rates due to their simpler construction, their lower light loss, and their increased viewing angle, it is hard to not consider them for any lighting application design.